Chip Shortage Driving Demand for Electrical Engineers

If you’re an electrical engineer, this is your time to shine. As a result of the silicon chip shortage and companies’ scramble to come up with alternate solutions, electrical engineer recruitment is on the rise. Our recruitment agency is seeing a surge for electrical engineers and their skill set to offset shocks made by supply chain disruptions.

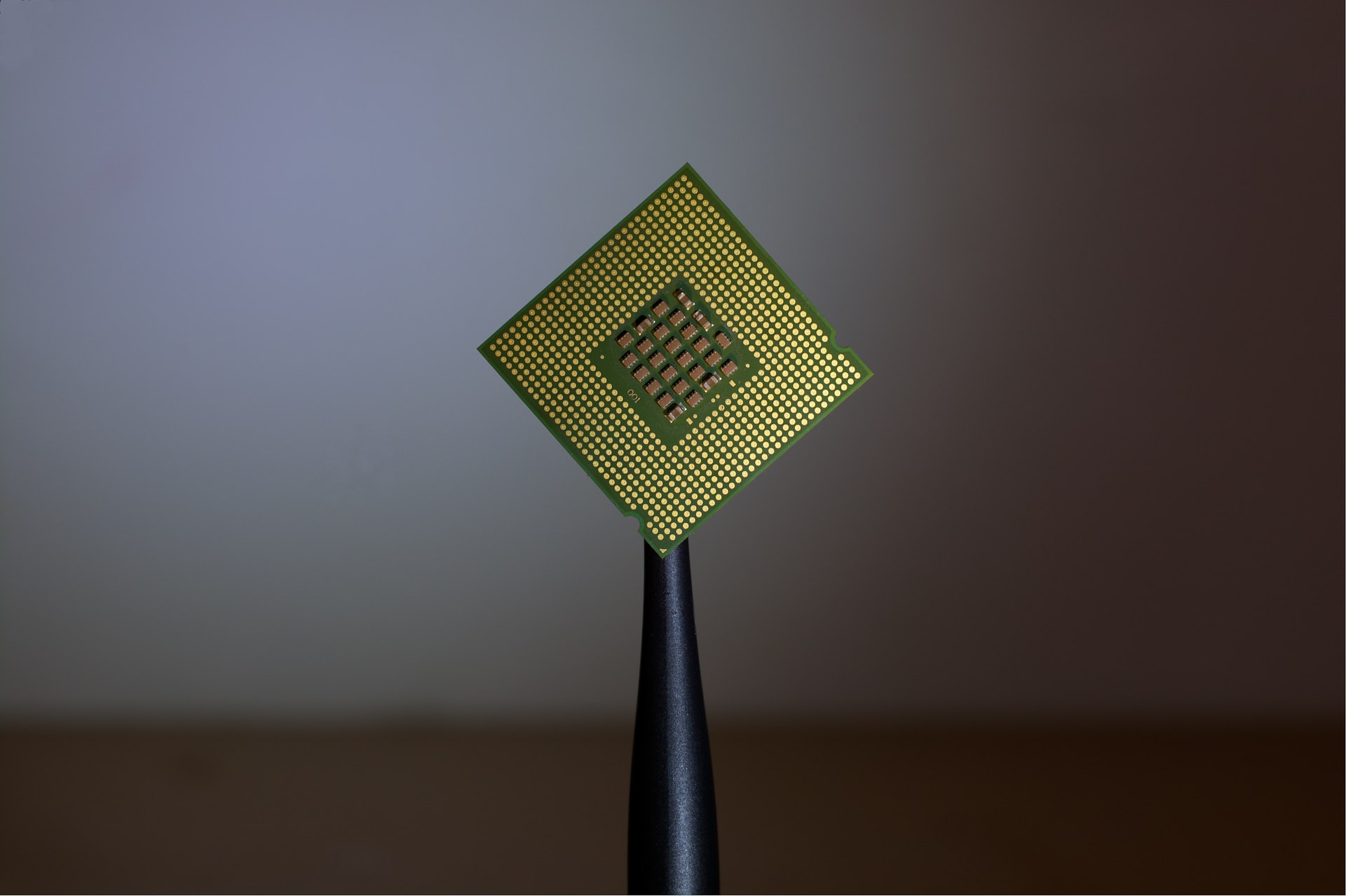

The COVID-19 pandemic triggered a global semiconductor chip shortage, and it is having major effects on the economy. Chips are everywhere: in phones, laptops, cars, and gaming consoles. Now, they’re running low. Manufacturers are working hard to increase chip production but with demand still high, the shortfall won’t be resolved immediately.

The extent of the shortage was unexpected, leaving many companies scrambling to find solutions. First, demand for consumer electronics soared once people began working and learning from home. In addition, automakers were forced to shut down or reduce production because customers were not buying cars. Now that factories have reopened and supply chains are operating at full capacity again, chip manufacturers have been unable to meet demand for both auto-specific and consumer electronics semiconductors. Some manufacturers were forced to cut their annual production volume by as much as 25%.

Engineering Through the Shortage

Aside from stockpiling inventory and paying fees for expedited shipments, companies are looking towards their engineers to pre-empt supply chain disruptions and actively find solutions when those disruptions occur. That demand will continue to soar, with the U.S. Bureau of Labor Statistics says that demand will continue to rise over the next decade.

Now, the shortage is forcing companies to turn to their engineering teams to quickly adjust the way the company designs its products to meet issues caused by the chip shortage. Recruitment for electrical engineers is on the rise because they are problem-solvers by nature, and there are two ways teams are approaching this issue: by designing for resilience and designing for availability.

Designing for resilience is an elegant way of saying “being prepared”. Engineers will ask themselves questions like, “What if the product gets damaged in transit?” or “What if the machines break down?” These types of questions might seem hypothetical, but they’re absolutely vital to companies in case of emergencies. This method should result in a long-term roadmap that clarifies how product architectures can be simplified and remove parts or components that could cause supply chain bottlenecks. Engineers are expected to predict what to do when major shocks happen, such as weather events and power outages.

Responding to Unexpected Changes

Many engineers may have not expected a pandemic, so their teams are designing for availability. At its most successful, people outside the industry may not notice a disruption because the disruption does not affect the product or business. But, the pandemic threw off many workflows and had people adjusting in real time to its issues. In one instance, Ford started shipping their Explorers without rear seat controls for the heating, ventilation and air conditioning. The driver still has the ability to control the system from the front seat. Ford dealers will install the semiconductor chips that control the Explorer’s rear seat heating and air conditioning at a later date. Engineers modify existing software to incorporate new components, adapt the current product to free up resources for more important capabilities, and use rapid prototyping and testing to validate the new designs.

Our recruitment agency predicts that the chip shortage will not ease anytime soon, especially as the demand for electrical engineers continues. Before the pandemic, electrical engineer recruitment was expected to grow as the world becomes more automated, with factories relying on robotics and other machinery to create complex microchips. COVID-19 lockdowns increased that demand as people spent more time at home. This time also highlighted a growing labor shortage within the industry. The Wall Street Journal reports that chip makers are fighting for talent to help find solutions. One Taiwanese powerhouse in chipmaking is seeing this issue firsthand, saying that the recruitment gap is at its highest level in more than six years. The good news for engineers is that the need for their skillset will continue to increase, as monthly salaries for chip manufacturing rises to one of its highest levels.

Another issue companies are having to deal with are counterfeit chips. The lack of chips on the market has spurred a huge influx of fake electronic components in 2021. In one report, a company called BotFactory turned to an unknown seller for chips. Despite the company’s suspicions before the purchase, they went with an unknown seller out of desperation. The company was able to receive a refund from a third-party dispute and eventually found semiconductors for its business. It’s not a new phenomenon that companies unable to find the semiconductors they require frequently turn to a black market.

High-Performance Teams Design Around Obstacles

The chip shortage is definitely an uphill battle, but this won’t be the first time that engineers will have to design around obstacles. From setting foot on the moon to present day, Amtec has helped to create high-performance teams to solve problems. Amid this chip shortage, many engineers are hard at work finding creative solutions with their ingenuity and skillset. We know they’ll get the job done!

Our Services

Industries We Serve